Battery Mould CONSTRUX Butterfly-System M6616

Battery Mould with 6 pockets

Year of manufacture: 2017

– Pocket dimensions: 7.00 m x 3.0 m

– 6 pockets

– 2 outer walls

– 3 butterfly formwork inserts

– Suitable for precast wall thicknesses: 15 cm to 30 cm

– Almost like new, as it was only used for a short time

Tilt Tables AVERMANN PREQAST-M6620-M25612-M25613

Tilt Tables, Width 4.5m and 3.0m

Hydraulic tilting table, Avermann, 13.00 x 3.00 m, 2 pieces M25611SOLD- Hydraulic tilting table, Avermann, tandem, 25.00 x 4.50 m, M25612

- Hydraulic tilting table, Avermann, Tandem, 17 x 4.50 m, M25613

- ADDED Hydraulic Tilt Table 2x, Avermann, 17 x 4.50 m, M6620

3-Table Folding Mould, NUSPL, PREQAST-M25608

3-Table Folding Mould

Technical Data

- Year of manufacture: 08 / 2016

- Manufacturer: NUSPL

- System configuration:

- Complete installation consisting of 3 tables

- Table size per table: approx. 3.0 m x 7.0 m

- Side tables:90° tiltable (tilting tables)

- Heating:

- Tables heatable (to support concrete curing)

- Maximum element height: approx. 1.80 m

- Wall thickness of elements: approx. 12 cm

Hydraulic Tilting Table GAERTNER, 7.20 x 3.90 m M25610

Hydraulic Tilting Table,

manufactured by Gärtner

– Table dimensions: 7.20 x 3.90 m

– Transport dimensions: approx. 7.30 x 4.00 m

– Tilting axis mechanically adjustable, left or right

– Heating pipes

– With vibrators,

– Steel covering, not suitable for exposed concrete

– Frequency converter for vibrators

– Hydraulic unit

Casting Beds 70m M25601

Casting Beds 70 m long, (formwork table, formwork bed)

Width 2.50 m

Composed of 6 x 12 m sections, each weighing 6 tonnes

Vibration is performed by the travelling paver

Manufacturer: SCHWINGHAMMER

For the production of precast slabs with lattice girders

Finished product width 2.50 m

Bed length: 70 m

Folding Tables 12.50 x 3.57m (and 3.10m) M25602 & M25604

for the production of Double Walls

a 1st turn over table 180°, length 12.50 m x width 3.57 m (+0.58 m for transport)

and a 2nd tilting table 85°, length 12.50 m x width 3.57 m (+0.58 m for transport)

Manufacturer: SCHWINGHAMMER

Year of manufacture: 2003

and another one which is 3.10m wide.

Hydraulic Molds for Columns, Trusses, Beams, Girders PREQAST-M25596 to M25599

Hydraulic Molds

M25596 Roof Truss Mold

Length: 31m, Height: 2m, Opening: 10-140cm

M25597 Bridge Girder Mold

Length: 33m, Height: 1.56m, Opening: 10-130cm

M25598 Universal Beam Twin Mold

Length: 39m, Height: 1.55m, Opening: 0.90m

M25599 Column Twin Mold

Length: 15m, Height: 0.80m, Opening: 0.80m

Battery Mould 10C, 8.5 m x 3.0 m, PREQAST-M25560

Battery Mould 10C

Year of construction: 1998

- Number of compartments: 10

- Compartment dimensions: 8.50 m x 3.01 m

- 9 partition walls à 6 to

- 2 outer walls à 10to, fixed outer wall standing on the right

- Suitable wall thicknesses: 12 cm, 18 cm, 20 cm have been produced

- Other wall thicknesses are also possible, depending on the base formwork installed.

HOWAL Stair Mold Variotop-Combi PREQAST-M25582

HOWAL Stair Mold Variotop-Combi

Reselling a NEW HOWAL variotop-combi stair mold for the production of straight prefabricated stairs with landings in overhead or side position.

- Manufacturer: HOWAL

- Year of manufacture: 2023

Prefabricated Stairs Dimensions:

- Max. number of steps: 18 (type 18/160)

- Running width: max. 1.60 m (shutter space plus holding magnet must be deducted from the nominal dimension)

- Incline infinitely variable between 150 mm and 200 mm

- Tread infinitely variable between 250 mm and 310 mm

- Core thickness is continuously adjustable between 100 mm and 250 mm

- Landing length: max. 1.60 m, landing extension from the 4th step, possible on every step

Progress M-System Mesh Welding Machine PREQAST-M25576

Progress M-System Mesh Welding Machine, Type Evolution 2012

- MMR Straightening Machine: 6 Wire Lines

- SWR Welding Machine: 6 Welding Heads

Further Dimensions:

- Max mesh size:

3.5 m width

9.0 m length - Cross & length wires diameter:

6, 8, 10, 12, 16 mm - Mesh characteristics:

Width up to 3,500 mm

Length up to 9.000 mm - Min. Width: 500 mm

- Min. Length: 1.000 mm

- Max. Bar Length: 9.000 mm

- Min. Bar Length: 500 mm

- Bar Length Tolerance: +-5 mm

- Bar Placing Accuracy: +- 10 mm

Reinforcement mesh can be custom-manufactured in a wide variety of grid patterns, dimensions, and wire diameters based on CAD specifications.

Each mesh is produced with zero waste and without the need for time-consuming cutting, unlike conventional standard mats.

The modular design of the welding system allows for precise adaptation to individual customer requirements.

ECHO Hollow Core Slab Plant (2019) PREQAST-M25581

ECHO Hollow Core Slab Plant

A complete production plant for manufacturing hollow core planks is available for sale in mint condition.

Has not been installed since its delivery in 2019.

The slipformer can further be used to produce foundation piles, solid slabs, beams, lintels, gutters, vine stakes, and even prefabricated slabs with insulation and integrated heating and cooling systems.

List of Equipment

- Cassette Beds: Length 120 m, 8 pcs, 960 m

- Stressing Bed Equipment: 1,20 m

- Slipformer S-Liner 50: 1,20 m

- Mold Set SC32x120/T50/1/6

- Mold Set Clima SC32x120/T50/1/6

- Mold Set SC50x120/T50/1/6

- Multi-Angle Saw MAS 1300, including Equipment

- Multi Functional Trolley MFT-50

- Unwinding Station for Strands/Wires/Cables

- Lifting Equipment: 1,20 m, 11pcs

- Tensioning Equipment, Stressing Jack, Hydraulic Pump, Grips, and Wedges

- Spare Parts

- Set of Abutments: 500tons

- Hydraulic Tilting Tables: 11.80 m x 4.00 m, 6 pcs

- Shuttering Magnets:1,800 kg, 120 pcs

- Concrete Transport System, Flying Bucket 2,500L, Rails, Crane

Pallet Carousel Double-Wall Production PREQAST-M24514

Pallet Carousel Double-Wall Production

- Manufacturer: Vollert, Nuspl,

Weckenmann, EBAWE, Filzmoser, RATEC, Unitechnik, SAA - Year of construction: 2020, 2019, 2017, 2003, 1991

Further Dimensions:

- Control system: Siemens S7, Unitechnik

- Pallets: 10.60 m x 3.08 m, 48 pieces

Consists of:

STRIPPING AND LIFTING

- Hydraulic tilting station: EBAWE company, renewed in 2017

- Lifting device for shell 1 + floor element (Weckenmann)

CLEANING, PLOTTING, ROBOT-SHUTTERING, AND OILING

- Automatic pallet cleaner

- Plotter

- Shuttering robot (Weckenmann, renewed in 2020 and 2003)

STEEL REINFORCEMENT, ROBOT, WIRES, FILIGREE GIRDERS

- Automatic longitudinal and cross-wire machine.

Diameter: 6-14 mm - Lattice girder preparation.

Automatic insertion robot for laying all bars, as well as the lattice girders. (Filzmoser)

CONCRETE DISTRIBUTION, VIBRATION

- Automatic concrete spreader: 3 m³

- 9 ejection augers + 9 flaps (Weckenmann/SAA company 2003, control replaced 2019)

- Electric vibrating station (Vollert)

CURING CHAMBER + AUTOMATIC PALLET STACKER CRANE (RBG)

- 47 pallet spaces, divided

- 47 insulated automatic segment doors (Vollert, extension 2003)

- RBG (storage and retrieval machine, Vollert 1991)

PROGRESS MSR 20 Straightening Machine PREQAST-M25558

PROGRESS MSR 20 Straightening Machine

- Straightening and cutting from wire coils

- Max. Production speed: 160m/min

- Wire diameter: 8 – 20mm

- 6 wire diameters guided in parallel

- Automatic and immediate selection of wire diameter

- Finished wire rod length: 500 mm to 14000 mm

- Rotor straightening system with hyperbolic straightening rollers (no damage to the wire surface)

Lattice Girder Welding Machine EVG-FIL GH400V-ST PREQAST-M24548

Lattice Girder Welding Machine

Rare machine for producing standard lattice girders and shear force lattice girders (German Market).

- Year: 2009

- Lattice girder welding line with variable feed 190 – 210 mm

- Type: GH400V-ST

- V stands for: Adjustable stroke (feed) between 190 and 210mm,

- ST stands for: Shearforce Lattice Girder

- Lattice girder height adjustable between 70 – 400 mm

- Minimum beam length: 0.8 m

- Max. Beam length: 16.0 m

- Basic width during production: 58 mm (inside diagonal dimensions)

- Finished beam width: 70 – 116 mm (outer dimension of bottom chords)

- Wire diameter upper chord: 5 – 16 mm

- Lower chord: 5 – 16 mm

- Diagonale: 4.5 – 9 mm

VIDEO-LINK:

FRONTSIDE-VIDEO: https://cloudlogin02.world4you.com/index.php/s/eZvgxj1nDPeyEoK

BACKSIDE-VIDEO: https://cloudlogin02.world4you.com/index.php/s/8Mrrzl4i3n0O3m1

BVM Rebar Shearline PREQAST-M25556

BVM Rebar Shearline

With pull-in system for bar diameters up to

40 mm.

- Built: 2006

- Model: HBSA-2.7H

- Serial No: 304

- Length: 16.7m

- Width: 2.25m

- Height: 2.40m

- Fully operational.

VIDEO-LINK: https://youtu.be/LEzZFOrVP0k

Lattice Girder CUT-System, GTA-PROGRESS PREQAST-M24543

Lattice Girder Processing GTA

Lattice girder CUT-system for storing,

measuring, cutting, welding, and distributing.

- Manufacturer: Progress

- Year of construction: 2012

- Lattice girder types: KT 800

- Lattice girder heights: 70 mm – 360 mm

- Storage length: 14 m

- Measuring length max: 10 m

- Measuring length min: 0.8 m

- Cutting grid: 100 mm

Interested in innovative projects?

www.preqast.com

Extruders NORDIMPIANTI, Concrete Hollowcore Planks, PREQAST-M24527

Extruders NORDIMPIANTI

- Type E120 year of construction: 2014

- Type EU2000I year of construction: 2012

- Type EU2000I year of construction: 2007

With moulding cassettes for thicknesses 150 mm – 500mm.

Including all accessories and spare parts.

Concrete Twin Wall Carousel Line VOLLERT PREQAST-M22452

Twin Wall Carousel

An efficient plant for the production of double/twin walls in the smallest space.

- Manufacturer: Vollert / Weckenmann

- Output per shift: 280-300 sqm ready-made twin walls in 8 hours.

- Number and size of pallets:

Pallet dimension = net table size:

7.00 x 3.02 m, corresponds to max. occupancy area. - Total of 44 circulating pallets

Digital twin for the simulation of all production processes is available!

PROGRESS Straightening Machine MSR16/5 PREQAST-M25575

PROGRESS Straightening Machine MSR16/5

Straightening and cutting machine with bending form No. 4.

- Year of construction: 1999

- 5 straightening rotors

- Diameter: 6, 8, 10, 12, 14 mm

- 5 reels, electrically driven and braked

- Outfeed 9 m with 2 bending heads

- Chain magazine for ejection at the rear

Cross transfer unit:

- 1 pair for transverse pallet transport

- Control cabinet with screen

PROGRESS Straightening Machine MSR16/5 PREQAST-M25574

PROGRESS Straightening Machine MSR16/5

Rotor-Straightener with double bending and a distribution magazine.

- Manufacturer: PROGRESS

- Year of manufacture: 1999

- Diameter: 6-14 mm

- 5 straightening rotors

- 5 decoilers

- 2 bending devices (Form4)

- Outlet: 10 m

Lattice Girder Processing 2 Lifts PREQAST-M25573

Lattice Girder Processing 2 Lifts

- Year of manufacture 2008

- Type: GTA 91/S

- Lift and storage system

- Hydraulic shear with measuring table

- Length 8m and lattice girder buffer

- Storage system with 14 compartments with

opposite vertical lattice girder storage rack - Double-sided lift

- 1 control cabinet and control panel with screen

Lattice Girder Processing Saw PREQAST-M25572

Lattice Girder Processing with Saw

Cut-off saw for cutting lattice girders to length.

- Various saw blades

- Lattice girder rack for 9 bundles of lattice girders

- Lattice girder rack for 4 girder heights

- Hydraulically height-adjustable with a hydraulic station

VOLLERT Carousel Wall Production, Palletsize 8 M x 4 M, PREQAST-M25568

VOLLERT Carousel Wall Production

Carousel Wall Production Line with Pallets 800 x 400 cm

- Make: VOLLERT Germany

- Year: 2018

- Finished precast products: Solid Walls, Floor Slabs, Insulated Walls, Multi-Layer Walls, Facade Slabs

Circulating Pallets

- Size: 8000 x 4000 mm

- Number of pallets: 50 pcs

- Max. thickness of walls: 380 mm (limit in the curing chamber)

VOLLERT Carousel Plant – Pallets 8 M x 3.6 M PREQAST-M25567

Carousel Plant VOLLERT Pallets

8 M x 3.6 M

Carousel Line with Pallets 800 x 360 cm

- Make: VOLLERT Germany

- Year: 2017

- Finished precast products: Solid Walls, Floor Slabs, Insulated Walls, Multi-Layer Walls, Facade Slabs

Circulating Pallets

- Size: 8000 x 3600 mm

- Number of pallets: 55 pcs

- Max. thickness of walls: 405 mm (limit in the curing chamber)

WEILER/MAX-truder Hollow Core Slab Production Line M25564

WEILER/MAX-truder Hollow Core Slab Production

Manufacturer: Weiler (now Maxtruder)

Year of manufacture: 2008

Operation: never been used.

WEILER/MAX-truder for hollow core slab and hollow wall production.

The line includes:

- a new original Weiler concrete batching plant,

- 2 shuttles (with trolley electric ways for 180m),

- cdistributor,

- extruder,

- tension plates,

- coverage machine,

- transport carts

- carrying mechanism for slabs.

HC Hollowcore Plank Production X-Tec/Elematic M25563

HC Hollowcore Planks Production

Manufacturer: X-Tec (Elematic), Finland.

Year of Manufacture: 2005

Condition: Never used in operation.

Includes:

1. Extruder – 1200 mm, up to 330 mm slab height, with an interchangeable 1200×220 mm matrix.

2. Universal machine for cleaning and pulling prestressing strands.

3. Universal cutting machine (with an angled cutting function).

4. Prestressing wire cassette tensioning station.

5. Universal trolley for covering mat.

6. End stops – 12 pcs.

LIEBHERR Mobilmix 0.5-C PREQAST-M24551

LIEBHERR Mobilmix 0.5-C

- Brand: LIEBHERR

- Discharge output: 30 m3/h

- Mixer size: 0.5 m3

- Mixer type: R/RIM

- Aggregate storage: 16 m3

- Two cement silos a 60 tons

AVERMANN Filigree Floor Half Slab Carousel PREQAST-M25553

Filigree Floor Half Slab Carousel

- Brand: AVERMANN

- 42 pallets 8.50 x 2.50 m

- Pallet cleaner NUSPL

- Pallet oiler and suction unit

- EVG-FIL RA-XE 14/5 straightening and cutting unit

- Lattice girder shears

- NUSPL vibrating table

- Crane with pallet traverse

- AVERMANN circulation control system

- Lifting beam for ceiling elements

EUROBEND Straightening Machine MELC 18-4-CNC PREQAST-M25555

EUROBEND Straightening, Cutting, and Stirrup Bending Machine

- Brand: Eurobend

- Type: MELC 18-4-CNC

- Year of construction: 2006

- 4-lane rotor roller wire straightening machine

- Straightening system: Hyperbolic rotor rollers (gentle to the wire surface)

- 4 flying shears

- Wire diameter: 8, 10, 12, 16 mm

- Suitable for 5-tonne coils

- Parallel operation of several lanes is possible

VIDEO LINK YouTube:

CLAYTON Container-Type Boiler House PREQAST-M24552

CLAYTON Container-Type Boiler House

- Productivity 500-1000 kg/h

- Working pressure 4-8 bar

- Equipped with water softening and alarm central

- Fuel: diesel fuel

- Container dimensions: L x W x H = 3000 x 3200 x 7000 mm, weight 9.5 t.

Cementsilo, Wilhelm Kurz & Söhne, 29m3, PREQAST-M24542

Cementsilo 29m3, Wilhelm Kurz & Söhne

- Manufacturer: Wilhelm Kurz & Söhne

- Year of construction: 1986

- Size: 29 m³

- Height of silo: approx. 10 m

- Width: approx. 2.50 m without ladder; with ladder approx. 3.50 m

- Location: Koblenz

Are you interested in innovative projects?

Visit www.preqast.com

Roller Conveyor for Rebar PREQAST-M24534 and M24535

Roller Conveyor for Rebar

Pos.1: 3-lane Roller Table

- Complete with all electric drives.

- Year of manufacture: 2015

- 3 frequency inverters, one for each track

- 1 frequency inverter for the transverse mode in the control box

- Length 15m, width 2.50 m

Pos.2: 1-lane Roller Table

- Complete with all electric drives

- Relay controlled

- L=14 m, W=1 m, H=1 m

- Weight: approx. 3 tonnes

- Available immediately

Straightening and Bending Stirrups FIL-Betasystems M24533

Straightening and Bending Stirrups

- Straightening and Bending Stirrups

- FIL-Betasystems COMBI 14/5

Year of manufacture 1997 - Wire diameter from D=6mm to D=14mm

- 5 wire reels

- Automatic diameter change

- New Siemens PLC control system installed in summer 2019

- plus 6 picking trolleys that can be transported to the production tables

- The control system enables the production of straight wires from the spool, in diameters 6-14mm

Hog Slats Tilting Machine PREQAST-M24517

Hog Slats Tilting Machine

- Date of manufacture: 2013

- Output: 75 pallets per 8 hours. It works with three different molds simultaneously.

- Each pallet can have a different mold.

- Molds can have 1, 2, or 3 product segments.

In theory, 75 pallets with a mold containing 3 product segments would equal an output of 3 x 75 = 225 ready-made products.

In the case of moulds with only one large product segment, the output for ready-made products equals 75 pallets per hour.

Different varieties can be produced simultaneously during one production cycle.

ACOTEC Production Line ELEMATIC PREQAST-M24515

ACOTEC Production Line

This offer comprises 2 ELEMATIC production lines and also includes a FRUMECAR batching plant.

- Manufacturer: ELEMATIC

- Year: 2019

- Output: 160 m2/h

Acotec panels are precast, non-load bearing partition walls.

They are room-high (max. 3.20m) and 600 mm wide, with a tongue and groove design along the vertical edge.

The panels are 6 times faster to install than traditional brickwork and twice as fast as blockwork.

ACOTEC Video Links

Acotec Partition Wall Installation:

https://www.youtube.com/watch?v=QtIMyD68LlE

Acotec Elematic Production Line:

https://www.youtube.com/watch?v=iR7xVL6N3ZI

Retaining Wall Moulds M23483

Moulds for retaining walls,

A-shape and L-shape

- Double Mould: Each mould can produce 2 elements per fill

- Up to 3m high, with spacers for 2.4m high elements.

All moulds have roll-away sides and end with a solid centre divide.

- H=3 m, L=1.20 m, W=1.50 m

- 6 moulds available

ECHO Slipformer, 6x, 1200 mm, Pre-stressed Hollow Core Slabs, M23498

ECHO Slipformer, 6 pieces

- Years of construction: 1997 to 2004

- Production width: 1200 mm

- Hollow slab thickness: 100 to 400 mm

- Additional slab saw

Passenger Lift Shaft Moulds M23471

Passenger Lift Shaft Mould 3 sizes

- Manufacturer: NINIVE

- Year of manufacture: 2011

- Usage: only 2 years in use

- Hydraulic adjustment

- Height of each mould: 3,20 m

LIFT SHAFT MOLD 1: 1600 x 1750 mm

LIFT SHAFT MOLD 2: 1600 x 1800 mm

LIFT SHAFT MOLD 3: 1600 x 1950 mm

For the production of lift shaft elements for vertical storey connection.

Delivery of considerable advantages for prefabrication in terms of time, costs, and flexibility.

Inserts, empty conduits, and switch bushes for the electrical installation can be installed according to the customer’s plans. The need for subsequent surface installation is superseded.

Time-saving installation aids such as anchor rails, transport anchors, scaffolding sleeves, anchors, etc., are already installed at the factory.

The smooth formwork on visible surfaces can be left unfinished, plastered, or painted over.

Production in the factory results in very accurate dimensions.

Short assembly times.

HUMARBO Tilting Lay Machine PXV-3 M22445

HUMARBO Tilting Lay Machine PXV-3

This tilting lay machine is suitable for producing large-format components in the immediate demoulding process.

- Year: 2018

- Condition: good as new

- Production length: max. 3 m

- Product width: max. 1,400 mm

- Product height: max. 1,100 mm

- Load of product, mould, and table: max. 6,000 kg

- Product weight: max. 2,500 kg

The machine was used for test purposes only!

The Tilting Lay Machine is suitable for producing large-format components in the immediate demoulding process.

The most suitable components are bar-shaped, plate-shaped, or frame-shaped.

These can be foundations, slab and floor slabs, U-shaped shells, shaft bodies, angle elements, or large-format bricks.

The high daily capacity with only one mould and two workers poses a significant advantage.

The Humbarbo PXV-3 is a floor-moulding machine that demoulds concrete products by tipping them onto a flat floor or pallet (wood, steel). It is suitable for reinforced or non-reinforced products.

COOTE Precast Hollow Core Floor Production M22443

COOTE Hollow Core Floor Production

This floor machine was manufactured in 2004 and was first used in January 2005.

- Precast flooring measurement: 150 mm by 600 mm

- Mould length: 8m

Includes:

- Casting ends with a 150 mm mould

- Core extractor

- Turntable

- Oiler

- Concrete filler

- Pallet handler

- Pallet cleaner,

- Product unloader

- 200 pallets

- 1 m3 skip complete with rails from the mixer

- Electrical panels comprise Allen-Bradley and Mitsubishi equipment

Rotor Straightening Machine EVG FIL / RA-XE 14/5 M22433

Rotor Straightening Machine EVG/FILZMOSER RA-XE 14/5

- Year of manufacture: 2001

- Electric rotor directional drives

- Well-maintained system! Little used.

Includes:

- 5 roller rotor devices with electric drive

- Wire quick-change device

- Production direction: from right to left

- Max. feed speed: up to 140 m/min

- 5 electrically driven wire decoilers

- Protective fence in the area of the wire decoilers

- Wire run-out track for max. bar length

10 m - Beckhoff control: operable in manual and automatic mode

Sales Price: EUR 49.500,00

Laser Projection System for Precast Concrete Plant M22432

MECOON Laser Projection System

- Consists of 6 laser projectors

The system can display the contours of different components, recesses, and lattice girders separately.

Accuracy is assured by independent calibration of the laser projector. The laser system is set up fully automatically and quickly for accurate projection results.

Lattice Girder Welding Machine EVG-FIL GH300V M21405

EVG-FIL Lattice girder welding line with variable feed 190 – 210 mm

- Type: FILZMOSER GH300V

- Condition: Very well maintained

- Lattice girder height: adjustable between 70 – 300 mm

- Adjustable stroke (feed): between 190 and 210 mm

- Wires: 5-14 mm

Welding transformers: 250 KVA - 1 pc automatic girder run-off and stacking system: 12 m

The machine is in full operation and can be inspected during daily production.

Precast Mobile Access Aid NUSPL M21400

Mobile Access Aid

Mobile access aid for a precast tilting and lifting station.

The electrically movable access aid (ladder) runs along a rail fixed to the floor.

This allows for quick access to the upper end of the elements and safe work at height, particularly for tasks such as attachment to cranes.

The speed of the longitudinal movement is infinitely variable.

Common installation takes place along a tilt table.

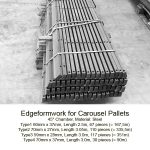

Steel Edge Formwork for Carousel Pallets A20376

Steel Edge Formwork 45° Chamber

The offer includes 4 pallets of steel edge formwork.

These add up to 944 m for the lining of circulation pallets for the production of filigree floor slabs, double walls, or solid walls.

B&R Controls in E-Cabinets A8258

B&R Controls in E-cabinets

The available used B+R controls for e-cabinets consist of 3 cabinets with various modules of B&R control racks, Hauser converters, and others

according the pictures.

Includes:

- B+R Provit Terminal

- Various B+R Controls

- A selection of electronic cards:

- NT44, CP70, PP60, PNC3, MARC

- EXS2, EXE3, E243, A, PNC8

- Hauser Servax Converter

What Is the Value of My Precast Plant?

How much money can I still get for my precast production plant or equipment?

To determine the worth of your production machine/plant, send us some basic information like:

- Brand/Type of the machine/ equipment/ plant

- Year/ capacity

- Condition and additional info i.e. photos

Send us an e-mail to or use the Request Form below:

Rotor Straightening and Cutting RA-XE 16/5 DBE M23503 **SOLD*

Rotor Straightening and Cutting unit EVG-FILZMOSER RA-XE 16/5

Straightening and cutting machine with double bending device 2 x 16 mm.

- Year of construction: 2004

- 2 movable bending heads at the outlet track

- 5 wire tracks for wire diameter: 6-16 mm

- Production direction from right to left

CONDITION

- In excellent condition, regularly maintained.

AREA OF APPLICATION

- In the precast concrete plant or the steel shop.

- Production of bars up to 12,5 m length.

- Production of bars with bent ends.

Gantry Crane 18 tons, Precast Yard M23495 **SOLD*

Gantry Crane

Gantry crane with new

DEMAG hoist, replaced in 2014.

- Lifting capacity: 18 to

- Lifting height: 10,75 m

- Span width: 23m

- 220/380V

- 50Hz

WIGGERT Batching Plant PREQAST-M25585 **SOLD*

WIGGERT Batching Plant

Scope of use: for Dry-Cast Concrete, Standard Concrete and SCC

- Manufacturer: WIGGERT

- Year of manufacture: 2010

- Capacity: 15 cbm/h

- Includes: Planetary mixer Wiggert 1125/ 750 fixed discharge

Very well-maintained, used dry-cast batching plant with row doser, completely integrated in the hall.