Year of construction: 2020, 2019, 2017, 2003, 1991

Control system : Siemens S7, UnitechnikPALLET CAROUSEL FOR DOUBLE WALLS

Pallets: 10.60m x 3.08m, 48 pieces

STRIPPING AND LIFTING

Hydraulic tilting station (EBAWE company, renewed in 2017)

Lifting device for shell 1 + floor element (Weckenmann)

CLEANING, PLOTTING, ROBOT-SHUTTERING AND OILING

Automatic pallet cleaner, plotter, shuttering robot (Weckenmann, renewed in 2020 and 2003)

STEEL REINFORCEMENT, ROBOT, WIRES, FILIGREE GIRDERS

Automatic longitudinal and cross wire machine, diameter 6-14 mm, lattice girder preparation,

Automatic insertion robot for laying all bars, as well as the lattice girders (Filzmoser)

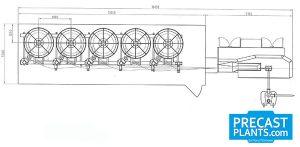

CONCRETE DISTRIBUTION, VIBRATION

Automatic concrete spreader 3m³, 9 ejection augers + 9 flaps, (Weckenmann/SAA company 2003,

control replaced 2019), electric vibrating station (Vollert)

CURING CHAMBER + AUTOMATIC PALLET STACKER CRANE (RBG)

47 pallet spaces divided, 47 insulated automatic segment doors (Vollert, extension 2003)

RBG (storage and retrieval machine, Vollert 1991)